Rotary blade sharpening jig

Another jig for a sharpening business.

Some large rotary knives needed sharpening for a machine which cuts fabric into strips for the side of a mattress. To sharpen these well a constant outer diameter and angle must be maintained. So it is time for a jig.

Knowing the size of the blade, the size of the grinding wheel, the height of the grinding wheel. We can do a rather basic study to work out how high the centre of the blade should be and how far away from the grinder it should be.

In theory I could make a fixed height stand but…

We all know how in theory can work out.

So an adjustable stand height stand is the best solution so that the height can be tweaked which allows the OD and angle to be tweaked

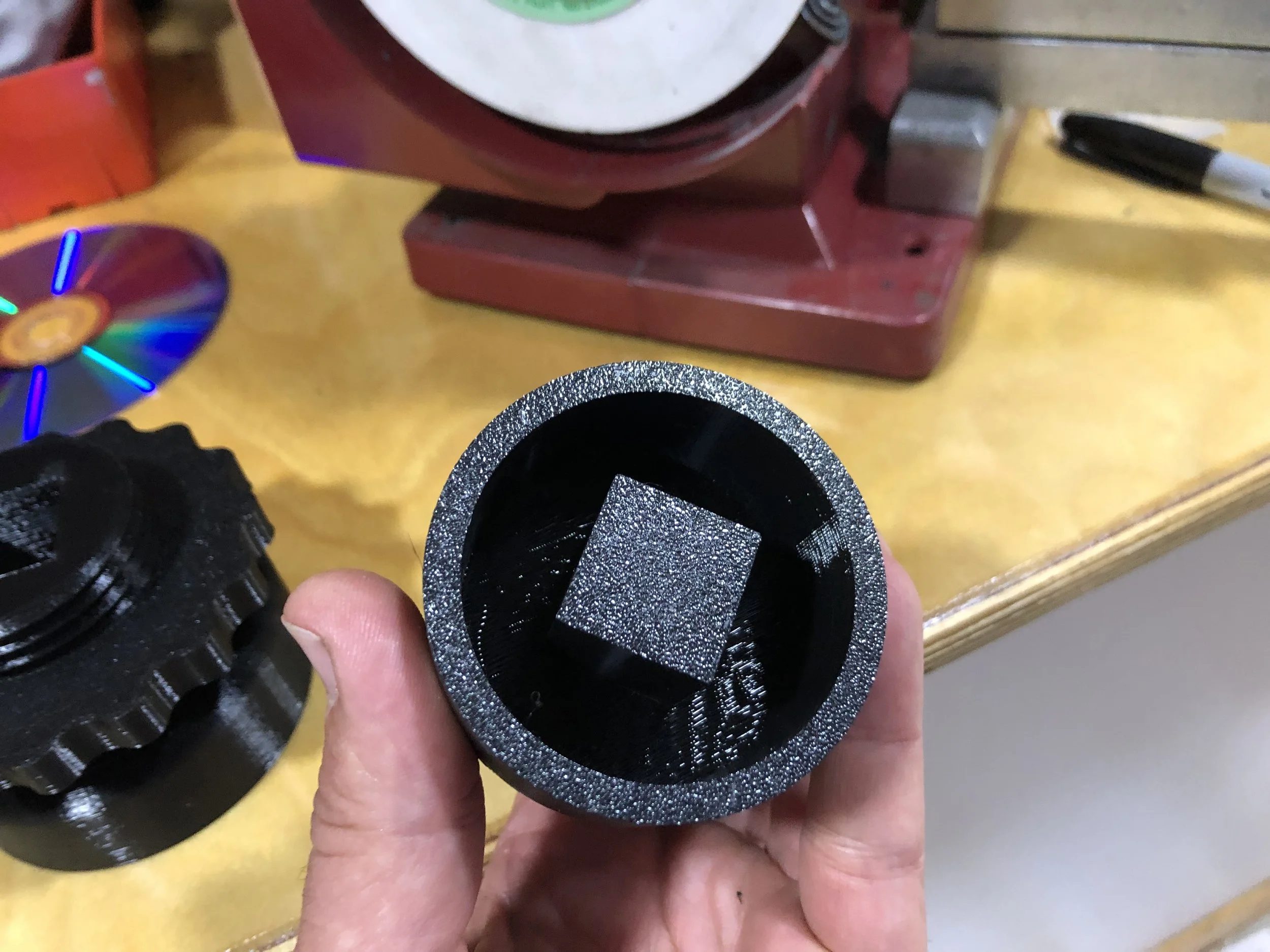

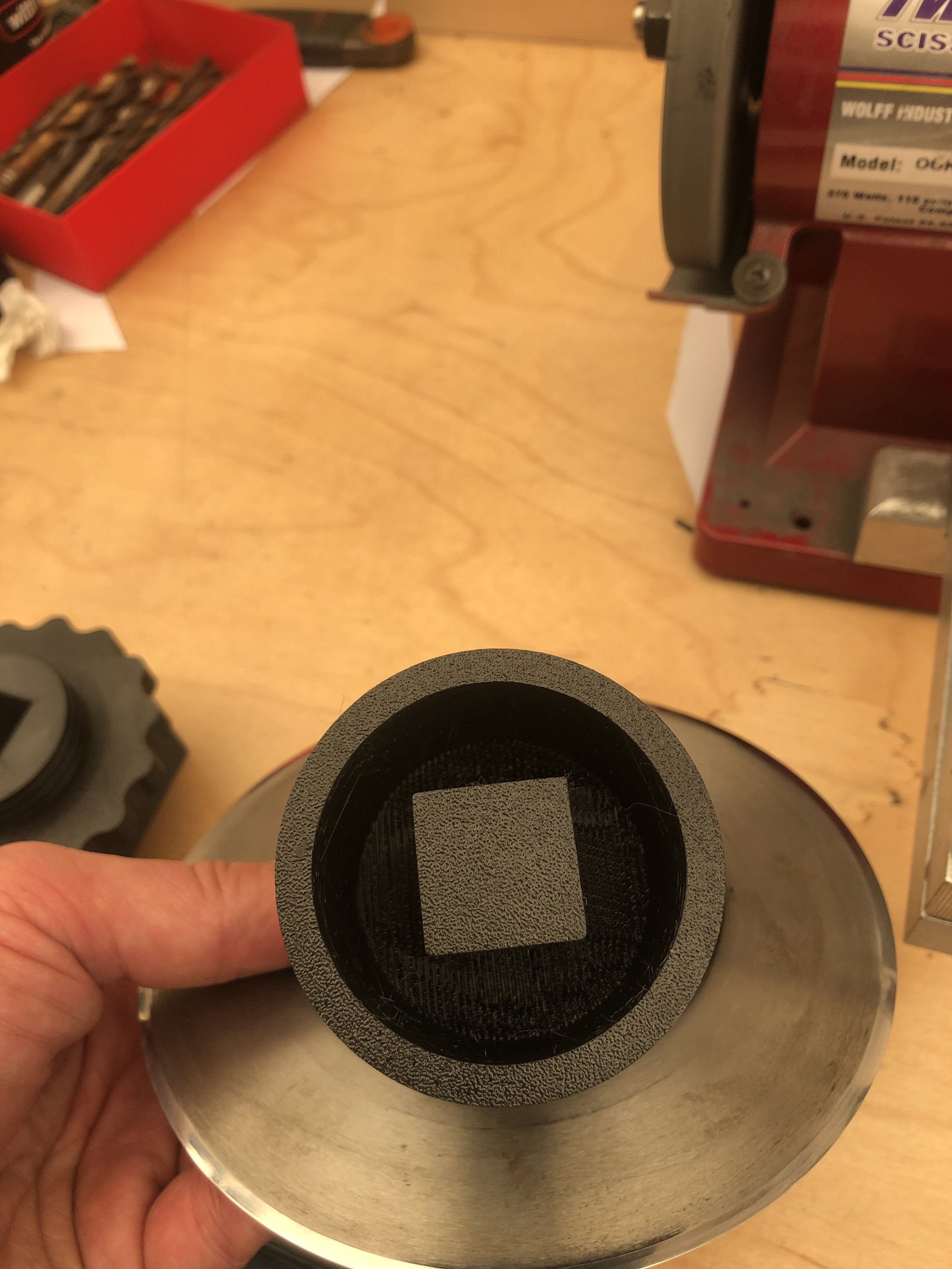

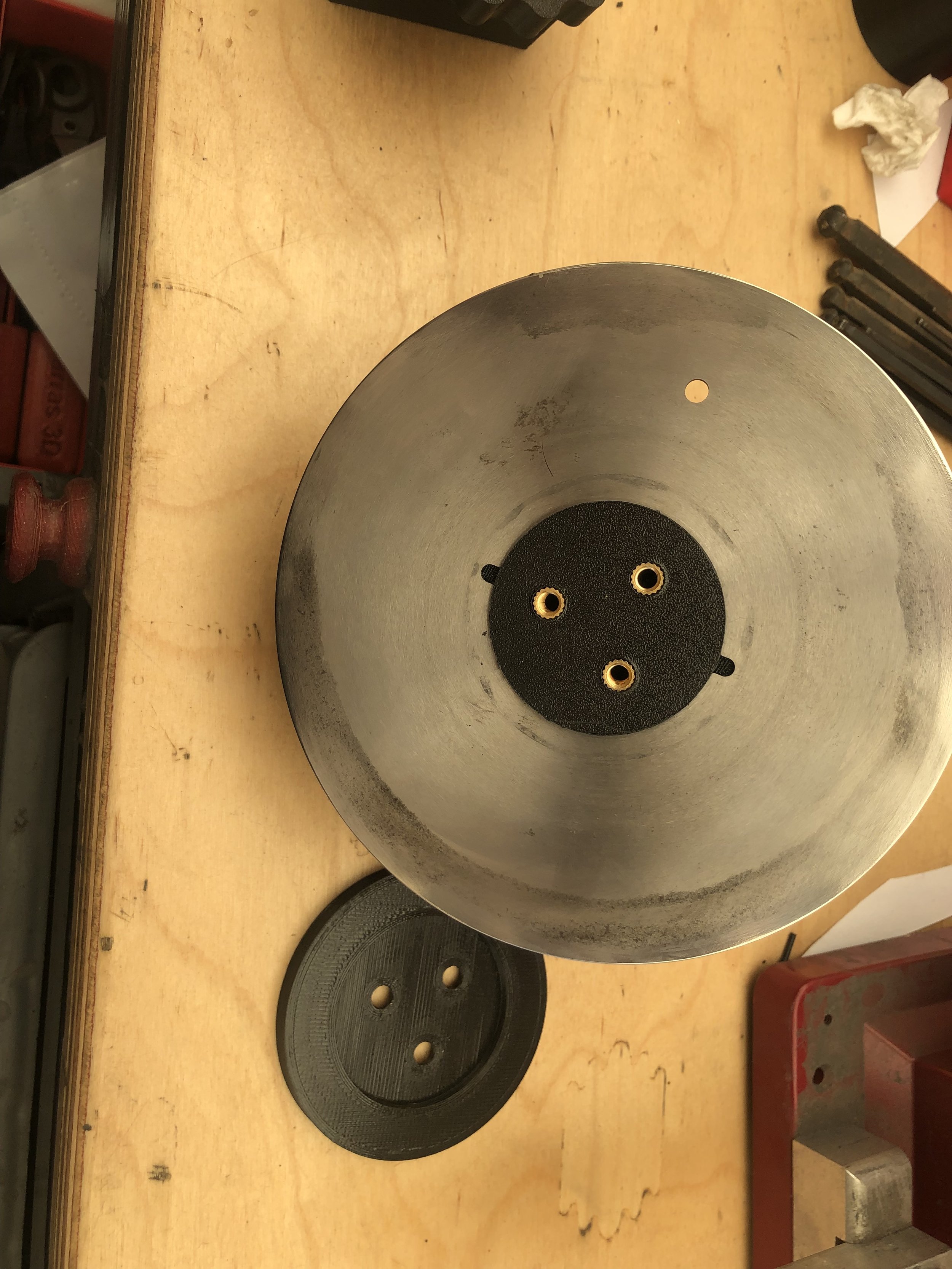

As the blades are round then there is also a way to spin them is needed. You could use the central hole on a peg but bearings are cheap and more accurate so a hub mounted on bearings is the solution.

For the adjustable height then a large thread is 3D printed with a nut underneath the top half to allow height adjustment.

The drawing below shows the details of how it all goes together. Bearings have been excluded as they wouldn’t bring any benefit in showing them. The hub has oversized holes as i would be using heat set inserts.

below is a gallery to show the final jig and some details on how it all comes together.

As to how sharp the blades where it did result in one employee ending up in A&E.